Call us for a free bid:

800-244-8286

Back

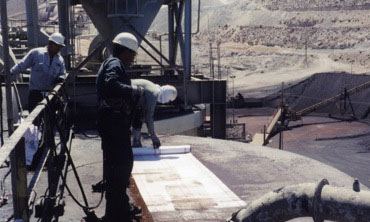

Mitsubishi Mining Company

Keeping Dry Under Difficult Circumstances

Mitsubishi Mining Company in Lucerne Valley California had a big problem. The storage silos for their finished cement products had leaks. Water seepage into almost any material is not good and for Mitsubishi, it was a huge problem. The leaking water made the powdered cement turn into hardened rock.

In one of the storage silos they were getting a lot of chunks of cement rock. Upon further investigation they found that they had pieces of cement as big as cars inside. They were so big that dynamite and jackhammers were used inside the silo to break them down into smaller pieces before they could be removed

This cost a lot of money as well as down time. They needed a solution that would stop the leaks and also stand up to the harsh environment of the hot desert and mining conditions.

Cement debris hindered access to machinery.

A heavy layer of cement over the silos covered everything.

After the roof deck was stripped of cement, it was ready for priming.

Part of the prep work was grinding down all penetrations to the original metal so a good seal could be applied.

Rubberized Emulsion & Polyester

Century Roofing introduced them to a tough waterproofing system that could take the abuse that was dished out from the mining operation as well as the harsh desert climate and continue to stay watertight. The system uses rubberized emulsion, polyester ply sheets and a final layer of white acrylic coating.

On top of the storage silos a large layer of cement built up over the years. This had to be removed before waterproofing the deck. Jackhammers were used on the larger pieces of cement and needle guns and grinders removed the material off of the roof deck, perimeter and equipment…a very expensive and time consuming process.

Perimeter metal and flashings were primed and two layers of an elastomeric compound and polyester were applied.

The original concrete deck was irregular. After the deck was primed, 6 gallons per 100 square feet of rubberized emulsion was applied to the roof deck followed by 1 layer of soft polyester. This process was repeated for a total of 2 layers. Using soft polyester allowed for the waterproofing system to mold to the concrete deck avoiding any air pockets or voids. A final coating of 6 gallons per 100 square feet of rubberized emulsion completed this phase of the job.

After the roof deck was primed all pitch pockets, boxes, flashings and equipment was sealed with elastomeric cement and soft polyester

Equipment and flashings are prepared on the primed roof deck.

A heavy coating of rubberized emulsion being applied on top of two layers of polyester and emulsion

Polyester being applied with rubberized emulsion

Cool White Roofing

After the rubberized roof cured, Advanced Coating’s Acu-Flex Acrylic material was applied. The acrylic coating blocks 100% of the suns UV rays and protects the new system from the hot desert sun. It will also stretch along with the rubberized material underneath, giving the roof flexibility.

Once the whole roof system was complete a walking deck was installed to all of the high foot traffic areas.

Upon completion Mitsubishi Mining received a 10 year warranty.

The job came in on time and on budget

Century Roofing has been using rubberized emulsion and acrylics for three generations. We have been combining them with tough polyester reinforcement material for 24 years. If you have tough, difficult or unusual waterproofing concerns, we can help.

The Finished Roof

Penthouse Detail:

1) All embedded concrete behind the wall was removed.

Penthouse Detail:

2) To keep the deck watertight a lead flashing was installed completely around the base as a counter flashing.

Penthouse Detail:

3) The finished roof

Spraying the first layer of Acu-Flex onto the roof deck

The roof with walking deck installed

The walking deck will help keep foot traffic from wearing out the roof.

Careful attention to detail was taken in waterproffing every aspect fo this roof. Each flashing and penetration was prepared and sealed. This is a much more effective solution than the previous "spray and pray" foam roof solution.

<

>

Century Roofing 3 Generations

8218 Ensign Avenue

Sun Valley, CA, 91352

License # 958049

Local # (818) 896-4351

Toll-Free # (800) 244-8286

info@thecenturyroofing.com

Follow us

Site Map

Home

About Us

Services

Projects

Contact

Testimonials

Why Do Roofs Wear Out

How To Save Your Roof

Why "Cool" Roofs Work

Inspections

Repairs

Restoration

Reroofing

Maintenance

Warranties

Industrial

Institutional

Cement Silos

Film Studios

Client List